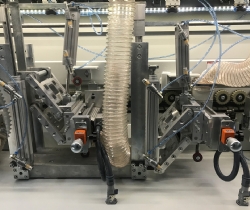

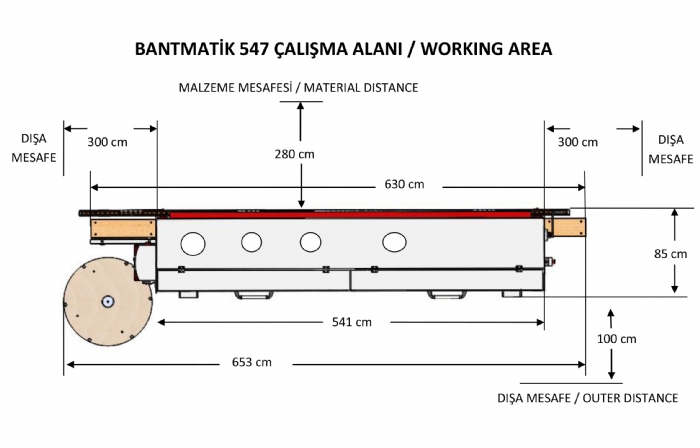

MACHINE LENGHT 5.7 METERS FROM DOOR TO DOOR. IT HAS TOUCHABLE SCREEN CONTROL PANEL AND 9 UNITS. WORKING SPEED IS 9 - 18 METER/MINUTE.

AIR COMPRESOR WITH AIR DRYER, DUST SUCTION MACHINE AND REGULATOR MUST BE USED FOR MACHINE. START-UP, INSTALLATION AND MAINTENANCE SHOULD BE DONE FROM UNVER WOODWORKING MACHINERY QUALIFIED TECHNICIANS. IF YOU DONT OBEY CONDITIONS, YOUR MACHINE LIFESPAN WILL SHORTEN. IT WILL NOT INCLUDED WARRANTY.

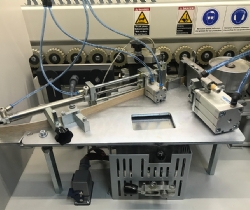

Touchable Control Panel

Use fastly with Pc controlling unit. Pratical and easy to use. Reach all past defect.You can learn total material and pvc band length.

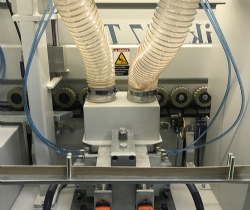

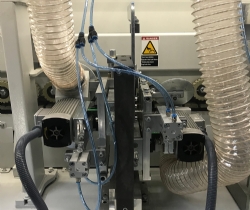

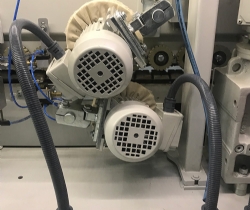

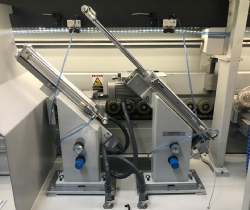

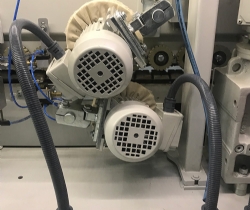

Pre Milling

2,2 kw, 8000 rpm 2 powerful motors pre-milling to 2 mm. Milling cutters can calibrated without unpick. All excelsiors absorbed by dust suction.

Infrared Heating

Milling pre-surfaces can heating infrared and drying. It prevents from wetness. Prepeares glue stick surface appropriately.

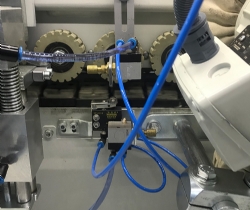

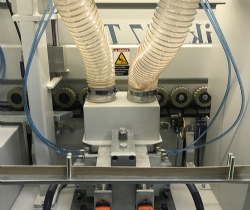

Glue Tank

4 liter glue capacity, ready 5-15 minutes. Stiffened and annealed glue roller.Preview glue stcik system. 4 kh bearing, back spring concept.

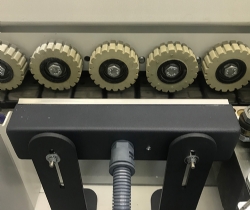

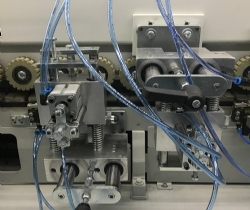

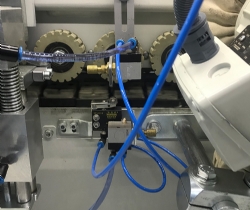

Press Unit

Press roller is adjusted by pressure, it rotates same as a palet speed. There are 3 press roller which is pressure adjusted. Press platform’s back and forward movement calibrated by indicator easily.

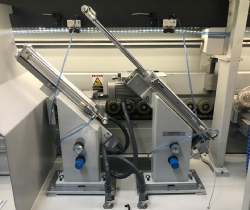

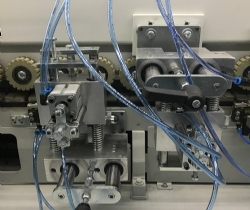

End Cutting

45° angled, pair of linear sled beginning-end milling unit. At 1200 rpm, it cuts beginning-end sensitively with high frequency motors.

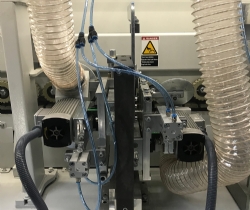

Bottom Top Milling

At 18000 rpm, pair of motor and four dynamic pneumatic automation systems. Tirim milling system, can choose parpendicular cornered, postforming or cover profils. 0,4 - 3 mm band thickness adjustment calibrated by indicator easily.

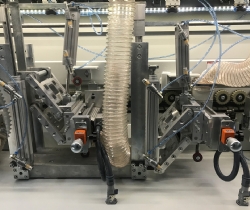

Corner Rounding

At 18000 rpm, pair of motor and four dynamic pneumatic automation systems. Tirim milling system, can choose parpendicular cornered, postforming or cover profils. 0,4 - 3 mm band thickness adjustment calibrated by indicator easily.

R2 Scraping

Using preview disk bright surfaces can scraping with radius. 0,4 - 3 mm band thickness adjustment calibrated by indicator easily

Cleaning Liquid

Glue remnants occur near the band edge. Glue remnant cleaning easily with solvent.

Buffer Unit

15 angled, forward-back and down-up polishing motors obtain clean and bright surfaces.

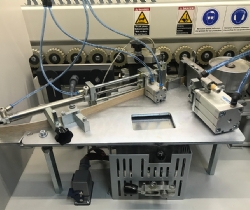

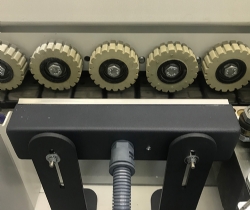

Tapping Pallet

M5 thread connected on the 1” strong bridged chain, tapping palet and bearing top wheels, bright materials processing without scratch.